Conveyor belts

Go to… Download the PDF file

Technicals films and fabrics : Conveyor-belt-technical-data-sheet.pdf

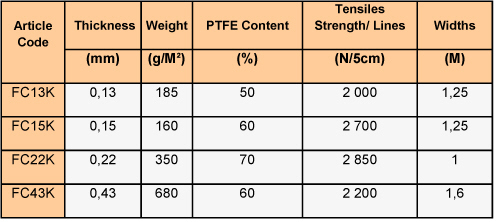

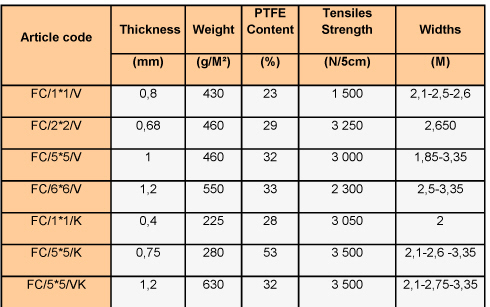

GLASS FIBRE/ PTFE IMPREGNATED KEVLAR

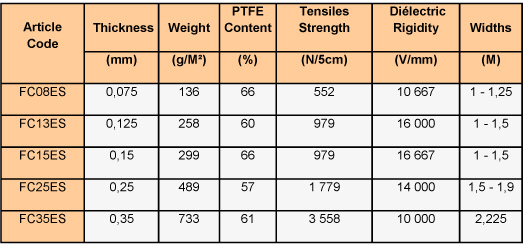

EXTRA SMOOTH QUALITY

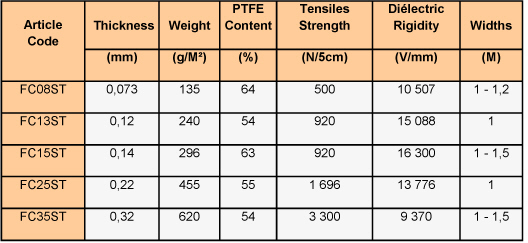

STANDARD QUALITY

PTFE COATED OPEN MESH FABRICS (Black anti-static)

(K : Kevlar, V : Glass fabric /Mesh 1*1,2*2,5*5,8*8)

Some of the above widths are not standard in stock.

KEVLAR FABRIC

This fabric is also recommended for small conveyor belts with high mechanical strength or for conveying on small cylinder diameters.

DESCRIPTION OF COVEYOR BELTS

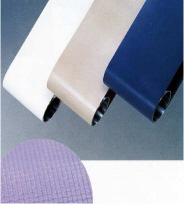

There is a considerable choice of PTFE and Silicone impregnated conveyor belts.

The choice of the weft is determined by: the products conveyed, the temperature,

speed, belt dimensions, type of guiding and traction, diameter of the rolls, demands

on the surface accordong to the products conveyed, stresses and strains…

Fabrics : Threadbare weaved glass fiber, carbon, or Kevlar ®, in open or closed mesh.

Conveyor belts with surface coating in :

PTFE, PFA, FEP

Glass, kevlar or composits weft

- 75 °c to + 280 °c / Thickness 0.08 to 1 mm

Rubber-base multi-ply reinforced wefts

- 40°c to + 110 °c / Thickness 0.5 to 3 mm

Coating :

Pure or carbon-filled PTFE, graphite, bronze, ceramic, silicone, pigments, PFA, FEP, MOS2

- Temperature : from - 260°c to + 280° c (non-adhesive)

- Temperature : from - 40°c to + 180° c (acrilyc adhesive one side)

- Temperature : from - 75°c to + 260° c (silicon adhesive one side)

Standard roll of 30 linear metres (possible 50, 100 ml and more possible). Width from 10 mm to 5 000 mm. Pieces pre-cut to your dimensions (mats, joints, membranes, baking sheet, protective curtains, dividers etc…).

Joints :

Belts can be delivered either : welded (non-detachale) or with detachable joints.

Type of jonts varies according to:

The load and tension of belt

The type and thickness of the fabric

Welded Joints :

By lap welding from 25 to 50 mm according to the lenght and width of the belt and the diameter of the cylinders .

Detachable joint :

With metal stables :

Alligator: 2 types : large or small

Clipper : (both supple and having very good mechanical behaviour)

bonne tenue mécanique)

With glass needle : on crenel joint in glass fabric (for microwave).

Special for open mesh fabrics : Peek joint (to allow the conveyor belt to retain optimum permeability).

These detachable joints can be protected by a cover strip.

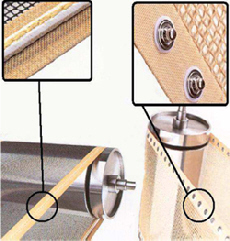

Reinforced edges

These strengthening pieces reduce fraying at the edges and provide guiding eyelets or studs with a stronger fixation surface. These pieces are generally 25 mm but can be of 50 mm in the case of very wide belts transporting heavy loads.

Edge-strengthening pieces can be in Kevlar in cases of heavy stresses and tensions.

Guiding

To keep the belt in a straight line, studs are recommanded. the distance between centres is 38 mm and there are of 12.7 from the edge.

Applications :

Hot sreen printing drying tunnel, ultraviolet, UHF, baking sheets for the food processing industry, conveying by shrink tunnels in the wrapping and packaging industry, the vulcanization of rubbers and heat-moulded plastics, continuous drying by convection, cooling, infrared, microwave, the manufacture of polyurethane foam sheets and cellular rubbers, onveying surfaces for the polymerization of epoxy resin in the manufacture of printed circuits, electronic components, optical parts (contact lenses), threads or adhesive products in tanks of solution, drying ovens, treatment of textiles, laminating, draining.

Domaines d’utilisation : transporting by shrink tunnels in the wrapping and packaging industry , for continuous drying by convection, in infrared and microwave techniques (silk screen printing…), cooking and transport belt (food industry, pharmaceutical…), the vulcanization of rubbers and heat-moulded plastics in the manufacture of polyurethane foam sheets and honeycomb structured material.